Enzymes

Filter

Filter

Antioxidant

ENDOZYM® Antibotrytis

Fining

ENDOZYM® Ice

Aroma enhancement

ENDOZYM® Thiol

Aroma enhancement

ENDOZYM® ß-Split

Aroma enhancement

ENDOZYM® Thiol Rouge

Aroma enhancement

ENDOZYM® Glucalyse 2.0

Maceration

ENDOZYM® Rouge HR

Maceration

ENDOZYM® Aromatic

Maceration

ENDOZYM® Cultivar

Maceration

ENDOZYM® ICS 10 Arôme

Maceration

ENDOZYM® ICS 10 Rouge

Maceration

ENDOZYM® Rouge

Maceration

ENDOZYM® Rouge Liquid

Maceration

ENDOZYM® Rouge Deep Skin

Maceration

ENDOZYM® Rouge Light Skin

Maceration

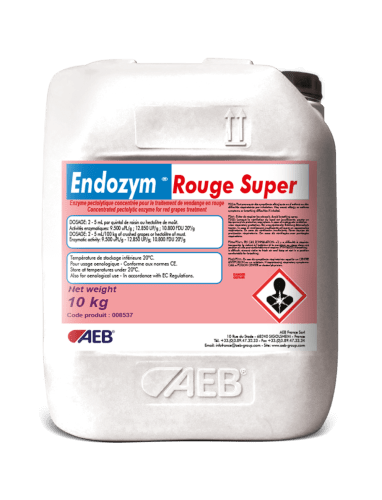

ENDOZYM® Rouge Super

Maceration

ENDOZYM® Cat-0

Maceration

ENDOZYM® Velluto

Maceration

ENDOZYM® Rouge Liquid XL

MICROBIOLOGICAL STABILIZATION

LYSOCID W

THE ENZYMES FOR WINEMAKING

The enzymes for wine consist of protein-type substances which act as biochemical catalysts accelerating the course of different reactions. AEB has invested numerous resource in attaining the most advanced production technologies, in response to the growing demand for quality and the request for enzyme preparations with high degrees of purity. Our Research and Development department works constantly with the fermentation broths of selected strains of Aspergillus Niger and/or Trichoderma Harzianum, for the recovery, purification and production of mixtures with specific enzyme activities.

AEB’s RANGE OF ENZYMES: PECTOLITC ENZYMES AND LIQUID PREPARATIONS

AEB’s range of enzymes offers a wide assortment of products to meet all the requirements of wine producers. To optimise the clarification of musts and wines, we have pectolitic enzyme preparations, as well as enzymes for treating grape rot, which inactivate the polyphenoloxidases found in the must. To improve the efficacy of flotation and shorten the time required for it, we have created a liquid enzyme for flotation. One of the most innovative products is a combination of two enzyme preparations specifically for thermovinification. We have formulations for: increasing the extraction of varietal aromas; aiding the clarification of musts obtained from low-temperature pellicular maceration; improving the extraction of thiol aromatic precursors to enhance the varietal aromatic characteristics of the grape. Our enzyme formulations also allow the reduction in the intensity of pumping over and maceration times.

To obtain an antibacterial action at the beginning of fermentation or bottling, our selection includes a lysozyme-based preparation with an antibacterial effect on lactic bacteria and gram-positive bacteria, in general. Lastly, to reduce the possibility of contamination by Brettanomyces, we have produced an enzyme formulation based on chitosan and yeast hulls which ensure the elimination of Brett yeasts and the absorption of volatile phenols, the compounds which give wine an unpleasant odour.