THE SUSTAINABLE WINE

OUR BIOTECHNOLOGICAL AND TECHNOLOGICAL SOLUTIONS FOR TARGETED AND PREVENTIVE OENOLOGY

In the wine sector, as in other agricultural sectors, the issue of sustainability is very much on the minds of consumers: consumers want wines that taste good and are produced with a minimal, if not positive, social and environmental impact. And so does the European Union, which is pushing for viticulture that makes less use of synthetic pesticides and has a neutral environmental footprint.

At European and Italian level there is no definition of sustainable wine, but there are shared elements, such as the prudent use of water, both in the vineyard and in the cellar, the adoption of circular economy practices, and the protection of biodiversity and soil fertility. Sustainability is now understood at 360 degrees: environmental, social and economic.

The production and research of biotechnologies and technological solutions is at the service of an oenology that is increasingly focused on and aware of the challenges that all professionals in the sector are facing and will face in the future.

We have identified three macro areas of intervention to support sustainable winemaking:

Technologies for saving energy and water

Biotechnologies for quality wine with reduced environmental impact

Technological applications to reduce sulphur dioxide in wines

1. ENERGY- AND WATER-SAVING TECHNOLOGIES

One of the applications where significant energy savings can be made is the discontinuous flotation of must: in fact, with E-Flot it is possible to reduce the refrigerants used to cool the must.

Discontinuous must flotation with E-Flot takes place at the same temperature as alcoholic fermentation. This is because the clarification is completed quickly thanks to a process by which gas is incorporated into the suspended solids in the must with the aid of clarifiers such as gelatine, facilitating their emergence towards the surface of the tank, as temperatures that are too low would increase the density of the must and negatively impact this process.

In static clarification or even continuous flotation, on the other hand, the must must be brought to a low temperature (usually around 5°C) because the timing of these processes does not exclude the risk of AF that would irreparably compromise the quality of the finished product.

Another method that allows significant energy savings is tartaric stabilisation by means of cationic exchange, which not only stabilises the wine but also lowers the pH. This is possible thanks to the plants in the Stabymatic range: the operation of these plants is based on the use of pH-Stab 2.0, a stabiliser composed of cation exchange resins, which enables the K+ and Ca++ salts in the wine to be reduced, making it stable.

Let us take as an example a base wine of 1,000 hL at 20°C.

With cold tartaric stabilisation:

- it is necessary to keep the wine for a minimum of 4 days at -4°C ;

- To raise the temperature from 20°C to -4°C requires approx. 350 kW (0.26 €/Kw/h = 91 € + the cost of maintenance for the days required to achieve stabilisation).

Another important issue concerns cleanliness in the cellar, an essential condition for quality wines. Often the word 'cleaning' is mistakenly associated with the concept of pollution or a negative environmental footprint. The following demonstrates that this conjecture is incorrect.

Premise: optimising detergency means speeding it up, speeding it up means saving water.

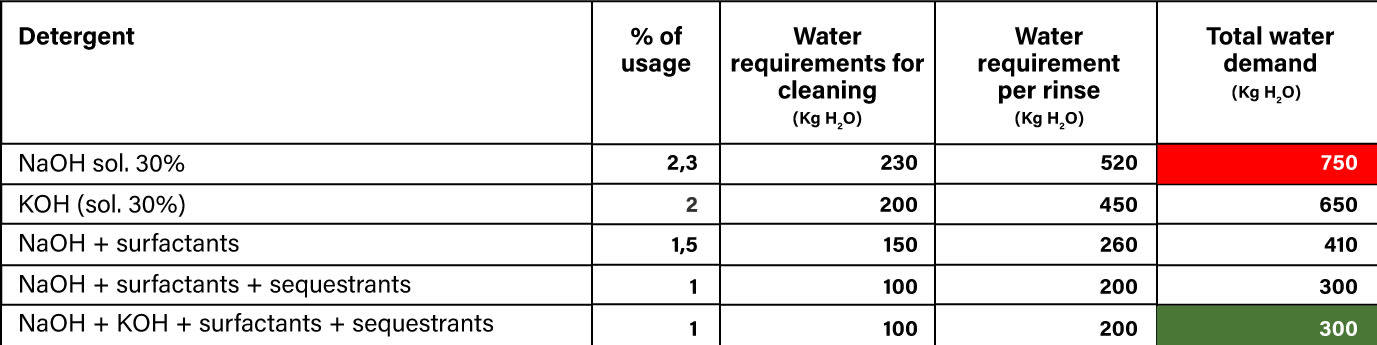

Today, it is possible to state that, thanks to specific protocols defined together with the wineries, water savings of up to 60% can be achieved (Table 1).

This saving is achieved through the use of complex detergents, formulated with wetting agents and ionic water hardness inhibitors that are more than 95% biodegradable.

Compared to products such as soda and potash, which require large amounts of water, complex detergents result in water savings during both washing and rinsing as they are used at lower concentrations. Furthermore, no hot water is needed to use these formulations, which means less energy is used for cleaning.

Table 1. Comparison of cleaning protocols: this table shows the water savings resulting from the use of complex formulations for cellar hygiene. They are not only used in lower concentrations, but also help to reduce the total water requirement by up to 60% compared to a product such as caustic soda.

2. BIOTECHNOLOGY FOR QUALITY WINE WITH REDUCED ENVIRONMENTAL IMPACT

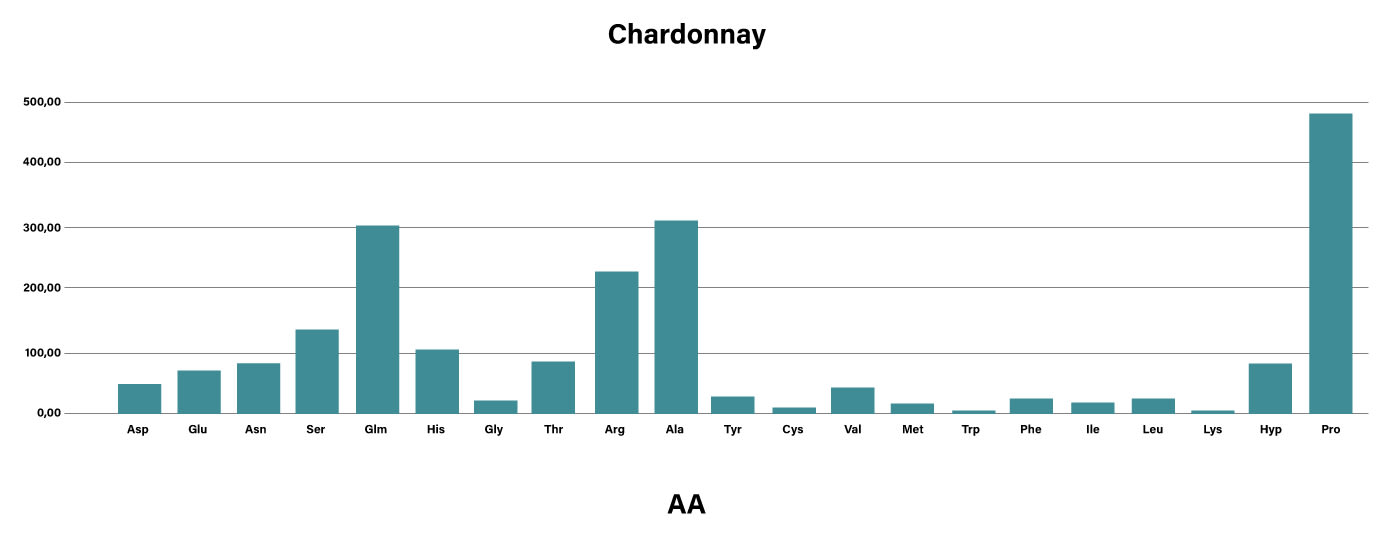

Nutrition - in this sense - also plays a fundamental role: in particular, the availability of specific amino acids enables the yeasts to conduct regular fermentation and, above all, enhance the varietal characteristics typical of the grape variety.

Below is an example (see Graph 1) of how in a Chardonnay grape it is essential to have enough amino acids in the raw material to guarantee the development of the aromas typical of this variety. Unfortunately, however, climate change has a negative impact on these compounds. Modern technologies for the production of yeast derivatives have made it possible to characterise the production of nutrients by integrating compounds such as: isoleucine (precursor of alcohols and amyl acetates), leucine (originates alcohols and isoamyl esters responsible for banana notes), valine (originates isobutyl acetates that give floral and white fruit notes).

Graph 1. Graphical representation of amino acid compound values for the Chardonnay grape variety.

With regard to wines made from grapes particularly rich in aromatic precursors, the presence of arginine in fermentation plays a role in enhancing typicality and helps to build an adequate aromatic profile.

3. TECHNOLOGICAL APPLICATIONS AIMED AT REDUCING SULPHUR DIOXIDE IN WINES

This species, naturally present on grapes, contributes to the taste and aromatic complexity of wines and its action immediately eliminates the normal dose of sulphur dioxide used in must of 50 mg/L (see Image 1).

It has also been observed that this strain makes it possible to obtain wines with lower volatile acidities, so the physiological increase in volatile acidity during the ageing period of the wines will still maintain acceptable values.

The technique of must bioprotection actually reduces the use of chemical additives in the must through the use of selected microorganisms. All this naturally benefits the environment, with a consequent reduction of the polluting impact when compared to that related to yeast production.

Image 1.

Graphical representation of the comparison between winemaking with and without Primaflora (AEB's yeast belonging to the non-Saccharomyces Metschnikowia pulcherrima strain).

Source: Study on the microbiological protection of must conducted by AEB in collaboration with the Unité Mixte de Recherche 'Procédés Alimentaires et Microbiologiques' (UMR PAM), the Institut Jules Guyot and the Université Bourgogne Franche-Comté (2016).

United Kingdom

United Kingdom