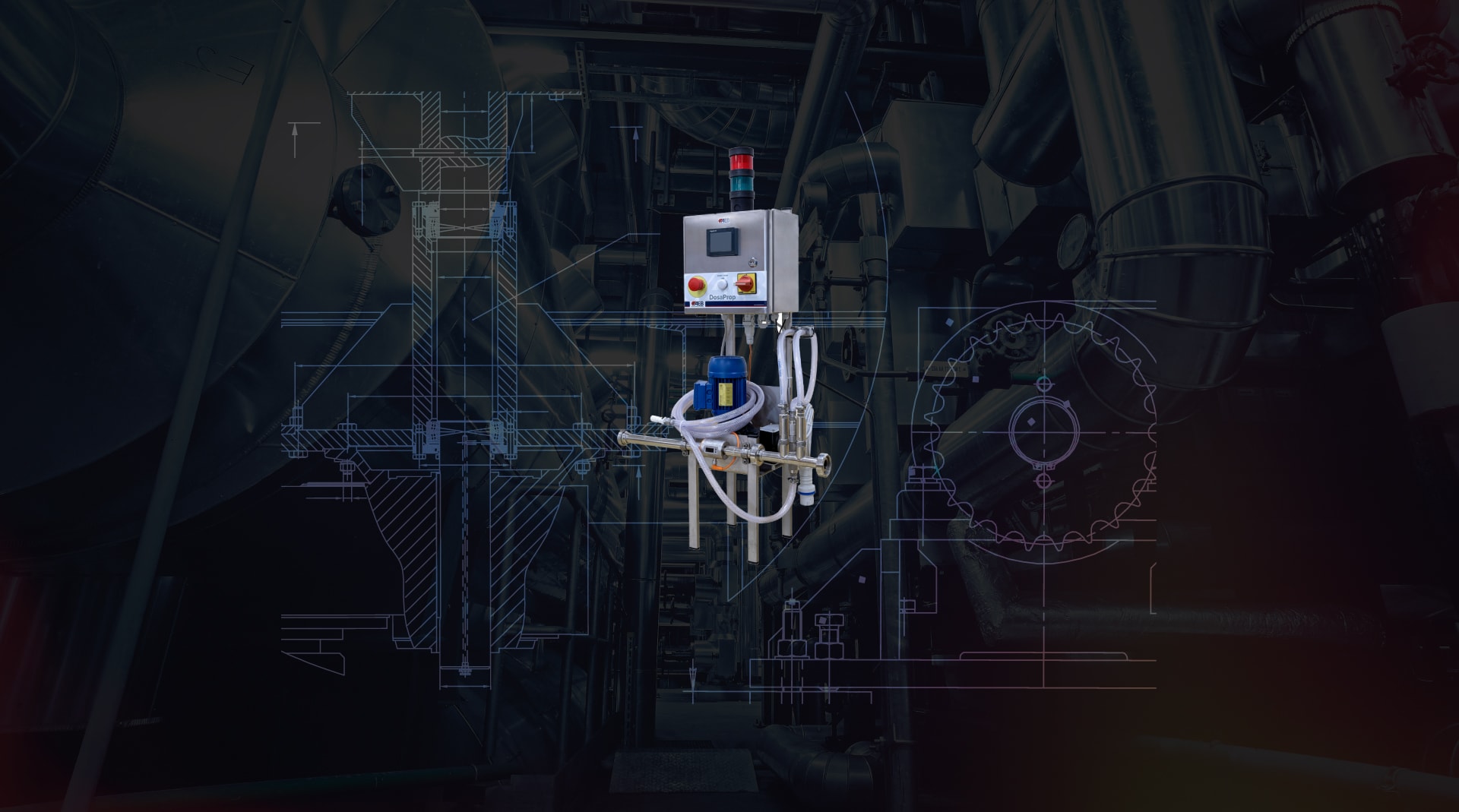

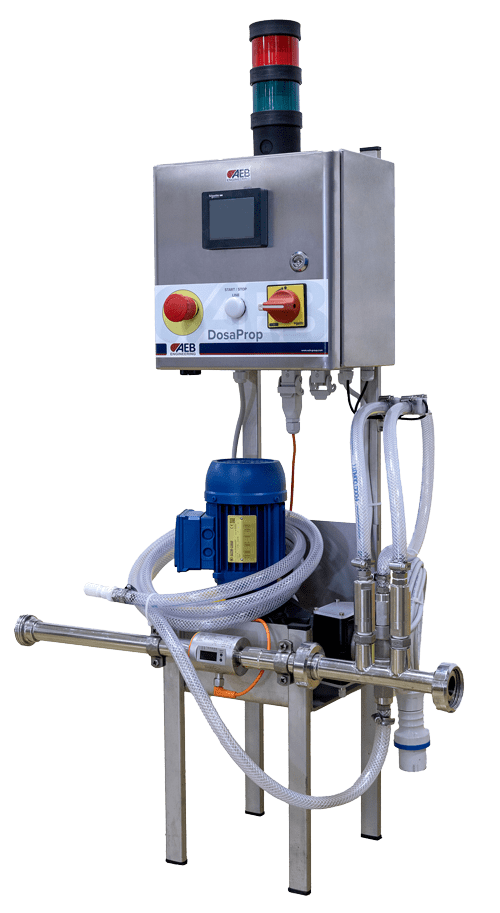

DOSAPROP

PROPORTIONAL LINE DOSING UNIT

Dosaprop ensures adjuvant liquid in proportion to be added proportionally to the flow in line and ensures perfect homogenisation. Its operation is based on a sensor that detects the amount of liquid flowing within the tube by sending the pulse to the dosing system for the addition.

BENEFITS

- Proportional addition of liquid adjuvants

- Uniformity and precision dosing

- Easy to use thanks to simple touchscreen interface

RANGE

The Dosaprop range comes in three models:

- Dosaprop, also available in a version with two pumps, which allows two different products to be dosed proportionally in line. This device is available for systems with hourly flow rates from 6 to 60 hL/hour (use in wine), 5.5 Hp.

- Dosaprop Hi-Flow, which achieves flow rates of 100 to 1200 hL/hr (use in wine/must/crushed grapes).

- Dosaprop Flux Set, can handle up to 3 pumps with an hourly dosage from 0.5 to 1000 litres.

The dosage of adjuvants can be dispensed from a maximum of 3 pumps and can be configured from 1 to 730 L/hour.

Calibrated non-return valves

PLC

Dosaprop flow detector

Dosaprop Hi-Flow detector

Stainless steel piston dosing pump

Optional dosing control kit: Adjuvant litre counter

Optional dosing control kit: visual indicator

Dosaprop Hi-Flow

Dosaprop Flux Set

China

China

United Kingdom

United Kingdom