HOW TO USE AEB FILTER SHEETS

If used correctly, AEB filter sheets guarantee excellent filter performance, with a reduced loss of product through dripping and low colour absorption.

To make the most of the filter media, it is important not to use damaged filter sheets or ones that have been tampered with and to handle the filter sheets with extreme care. When they are placed in the filter press, avoid knocking, bending or scratching them and follow the indications carefully given in our tutorial.

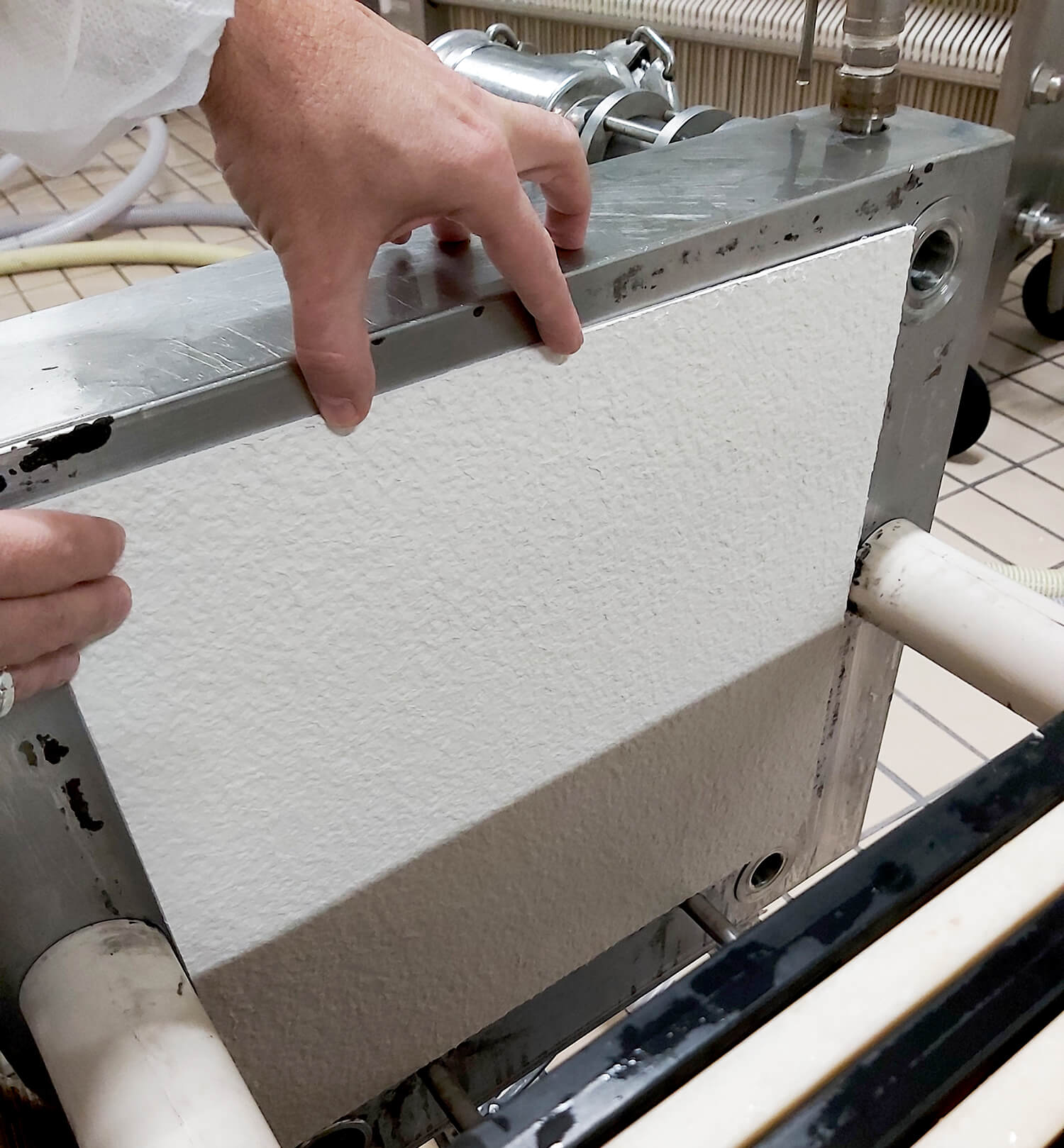

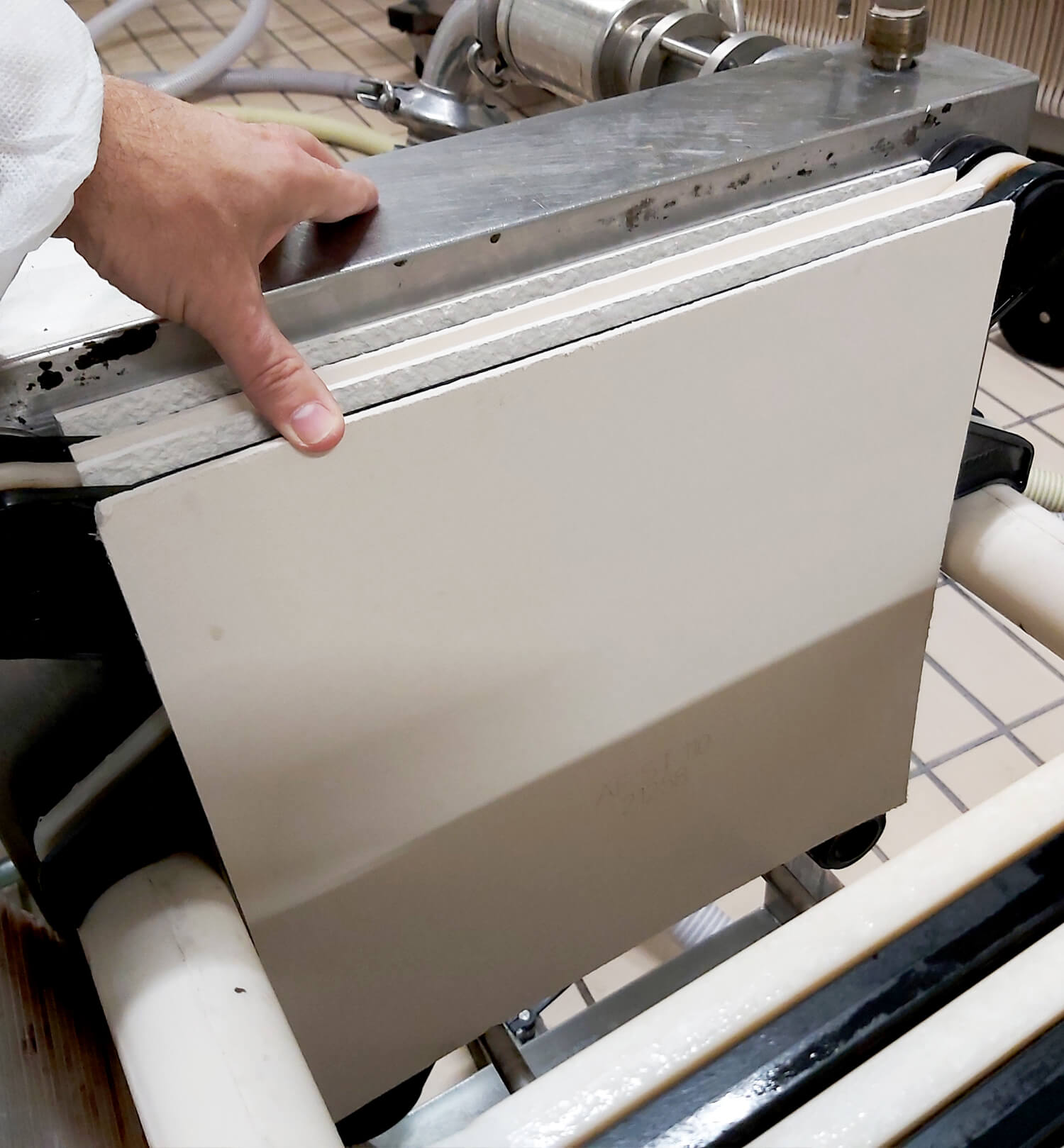

How to position the filter sheet

The filter sheet has a smooth side and a coarse side. The liquid should always enter on the coarse side and exit in the smooth side.

Coarse side

Smooth side

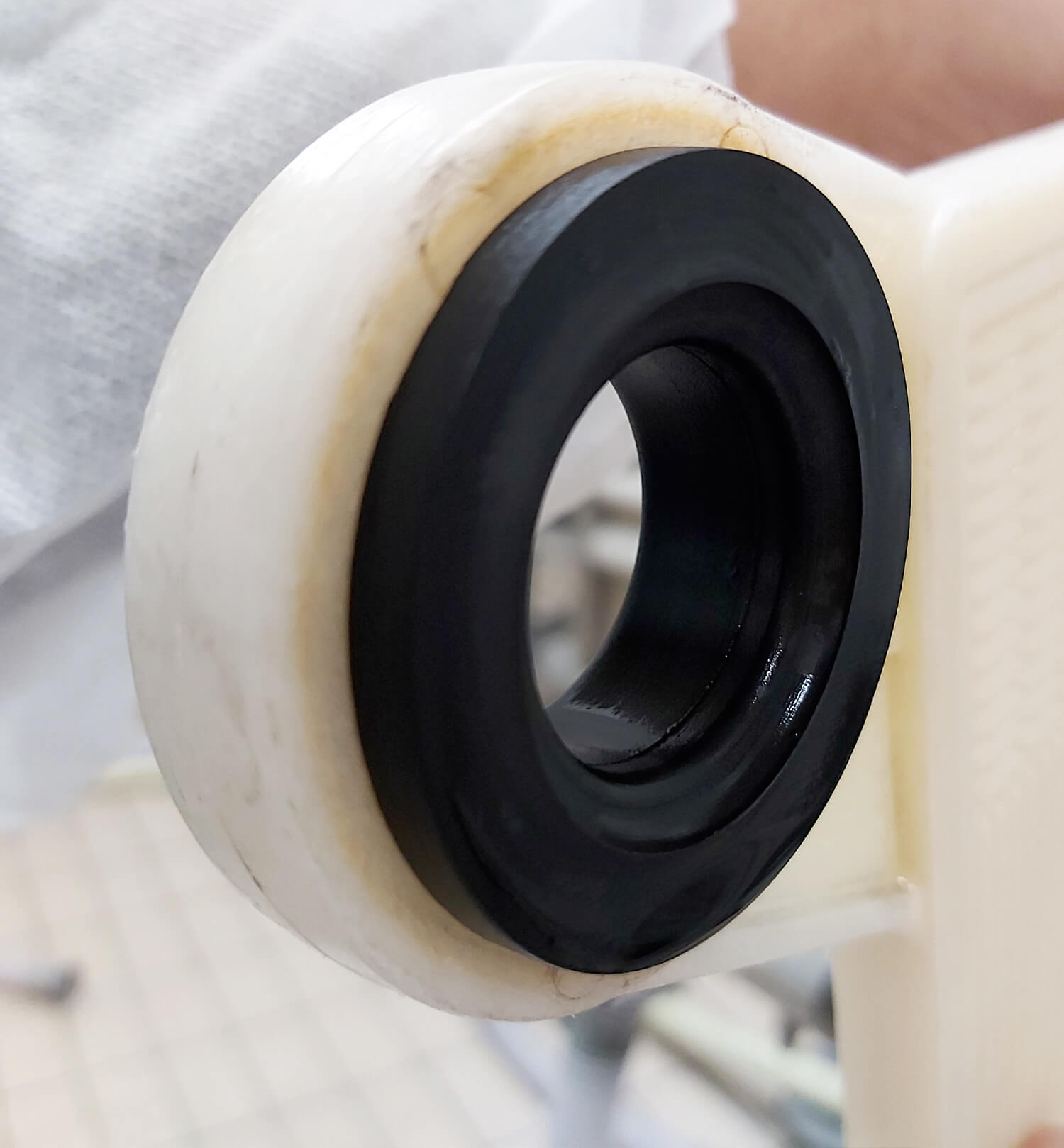

CHECKING THE STATE OF THE GASKETS

Check the gaskets for wear which could cause abnormal dripping from the sheet.

TUTORIAL ON HOW TO CORRECTLY ASSEMBLE THE FILTER SHEETS

HOW TO GET THE BEST OUT OF THE SHEETS

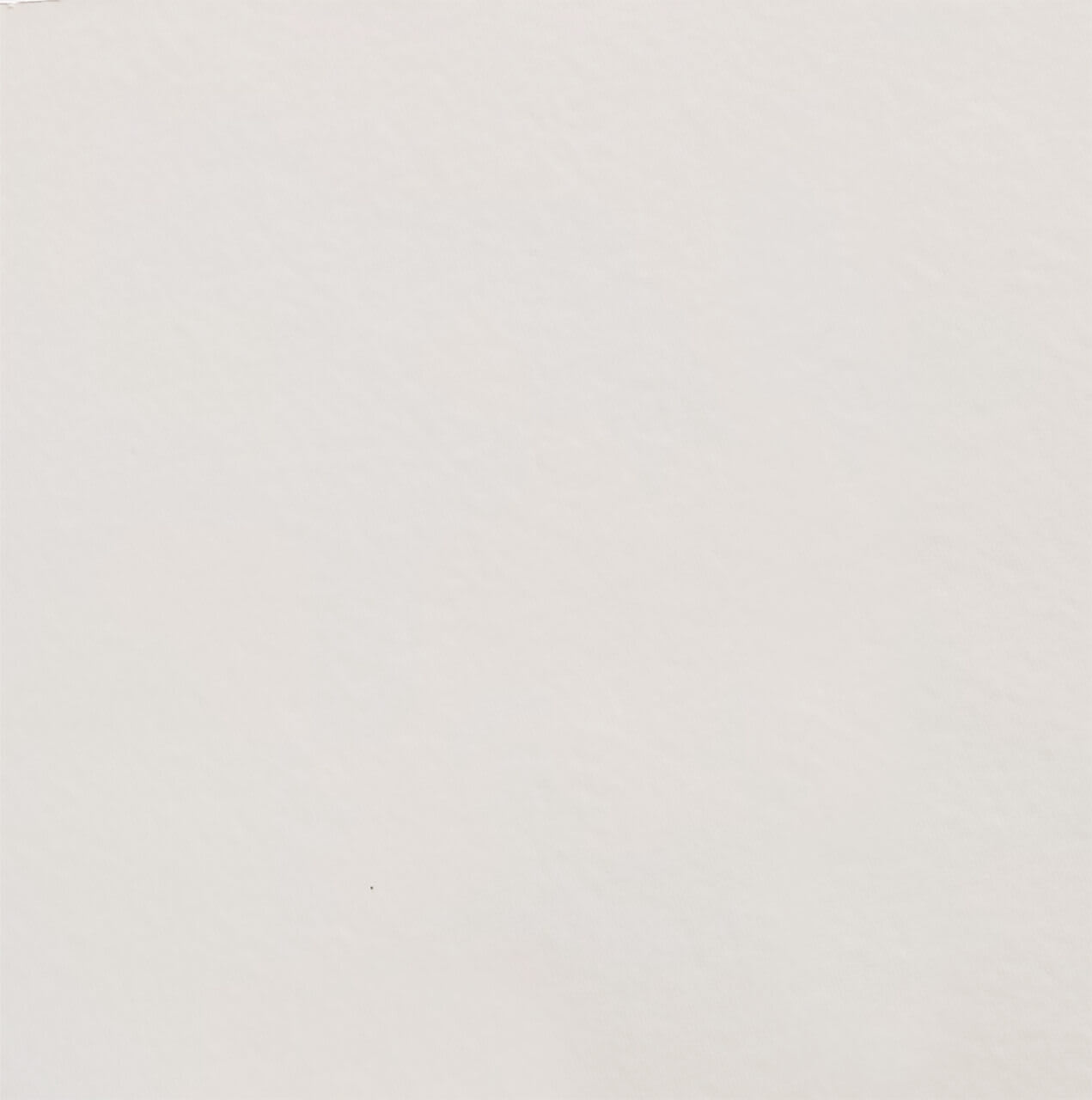

If you look at the image carefully, you will notice how under the line drawn, the filter surface is darker, which shows that the sheet has filtered more than the upper part.

The customer filtered a product containing carbon, but while filling the filter press system, the 4 side vents were not opened. This led to the filter being filled unevenly; consequently, the filter sheet (in this case 40x40) did not filter evenly.

You should always check this detail at the end of filtration to ensure that the filter has worked correctly.

Close-up of the sheet at the end of the filtration process where the vents are not opened when filling the filter press.

United Kingdom

United Kingdom